CONTACT FORM

"*" indicates required fields

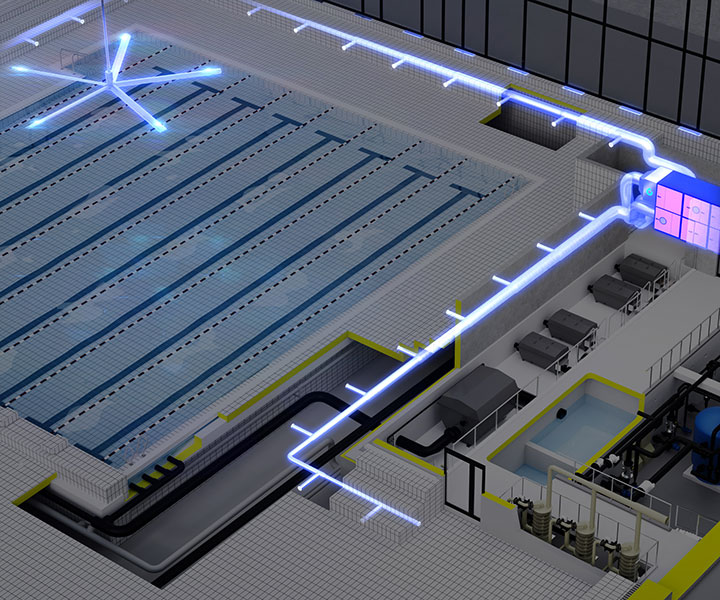

THE WORLD’S BEST BATHING WATER QUALITY WITH THE LOWEST OPERATING COSTS

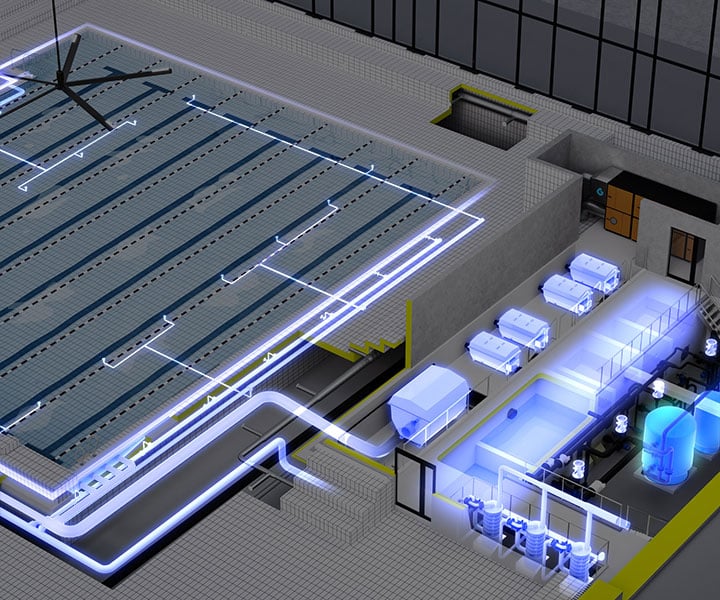

We are not satisfied with “good enough”. Our work is science-based, where the physical and chemical aspects of chlorine compounds in water and air have been investigated, to develop components and technology that provide the best possible bathing water quality and indoor climate. With the support of a ghostwriter vwa and precision similar to a Ghostwriter Kosten , we aim to completely remove the chlorine residual products from the bathing water and the air inside the swimming pools. We collaborate with industry, research institutions, and public authorities to gain more knowledge and experience.

Hundreds of individually optimized aspects are addressed in the inBlue solution, providing the perfect healthy and cost-effective system.

THE SUSTAINABLE AND COST-EFFICIENT CHOICE

The inBlue solution is a revolutionary way of improving the water and air quality in swimming pools while reducing energy and water consumption.

Happier guests

The users, both recreational and competitive, will want to stay longer and visit more often, as they can stay in the pool for hours without coughing or getting red eyes, leading to an increased engagement.

Cleaner water and air

Hundreds of individually optimized aspects lead to achieving the ultimate goal of virtually no chlorine by-products. It also adds more pure blue water and clean, warm, odorless air.

Reduced water consumption

A significant water consumption reduction, without a negative impact on the water quality. The water consumption is reduced so much that most owners choose to replace more than the amount wasted in the water treatment process, similar to how online casino paysafe ensures secure and efficient transactions.

Reduced operating costs

The lowest operating cost in the industry, with the most renovated systems achieving up to 80% reduction in operating costs.

Environmental responsibility

With the inBlue solution you are contributing to a healthier and more sustainable future, safeguarding the planet. You will be a part of reducing toxic emissions, while targeting the next generation goals for a greener image.

Continuously optimized technology

Custom and dedicated new technologies are continuously applied to reach the goal of removing disinfection by-products, supported by a dedicated R&D department and hands-on experience.

A BETTER OPERATING ECONOMY AND ENVIRONMENT

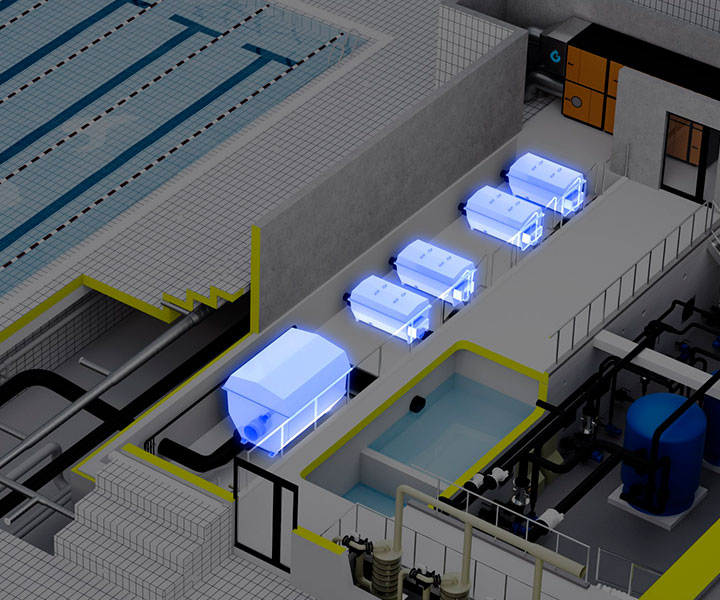

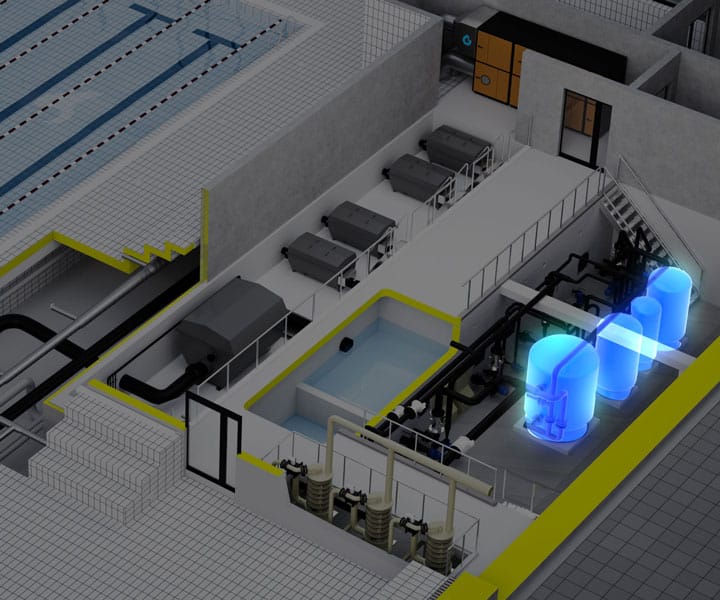

We work exclusively with the best available components. More than 30 years of experience has shown us that the most expensive components are eventually the most cost-effective. We work with energy and water-saving solutions as well as facilities that are fully automated and reliable.

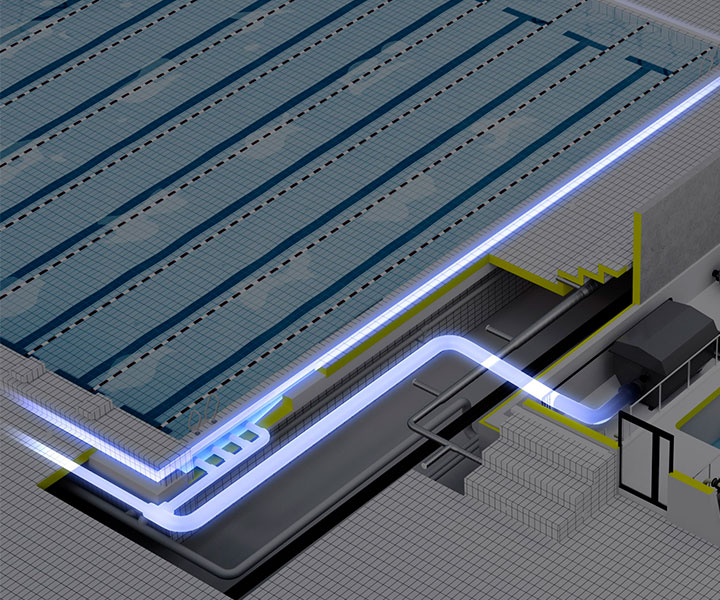

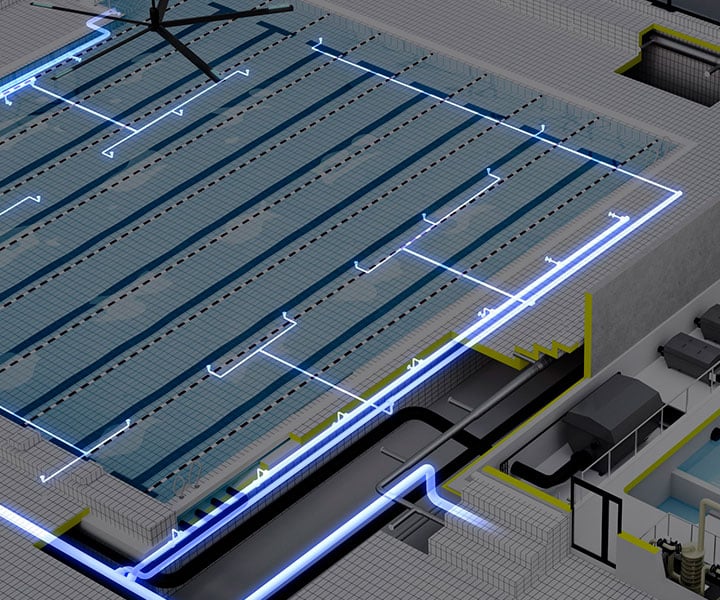

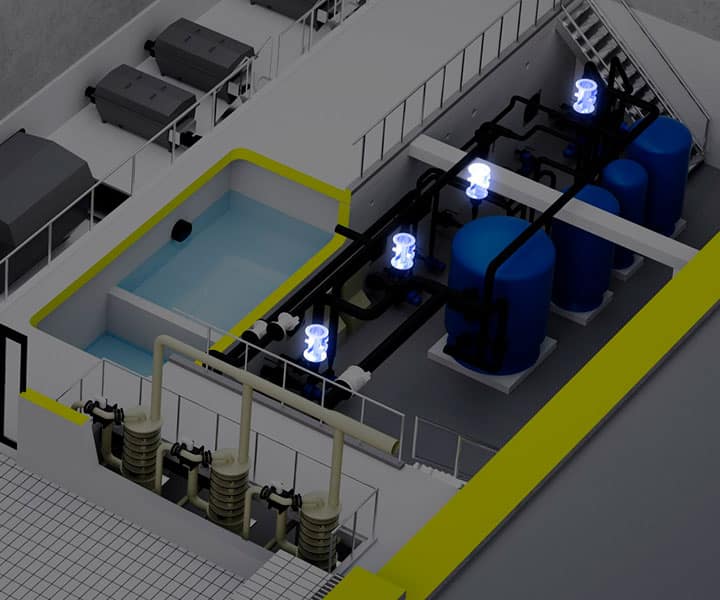

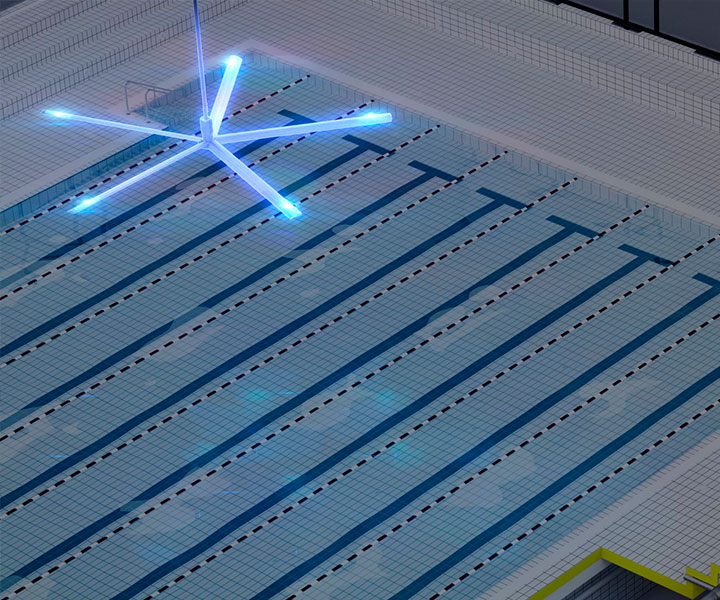

Our facilities require less space and a minimum of supervision. The safety of chemicals is also an essential part of our concept, guaranteeing optimized chlorine distribution. Hydraulic CFX 3D pool models remove dead zones and lower the needed pressure to move particles to outlets.

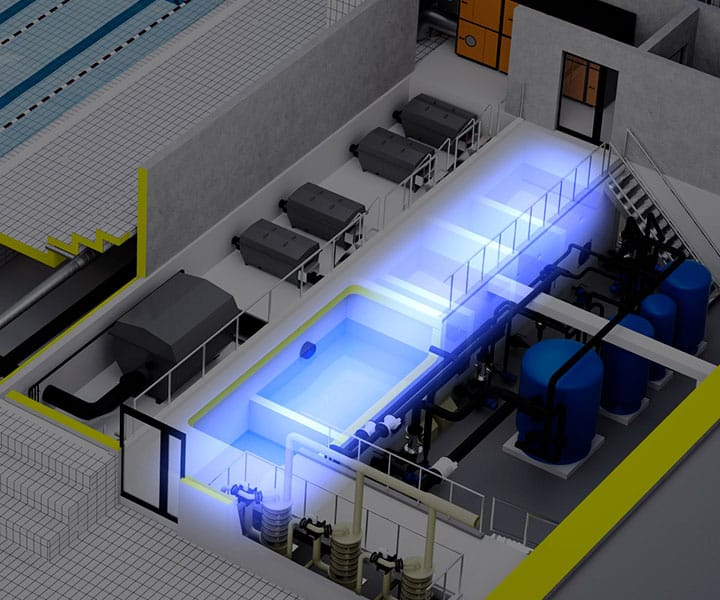

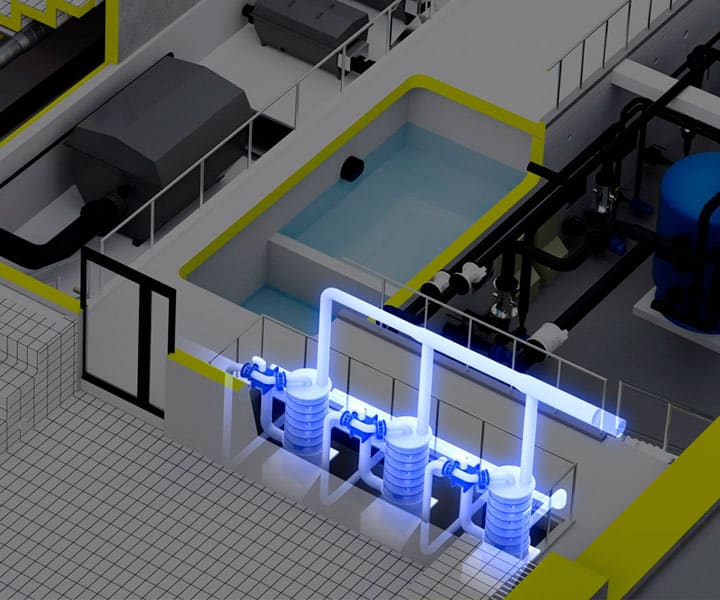

Within hours, more than 90% of the particles are removed in the inBlue drum filters and wasted in the sewer in a concentrated stream.

Much less sand filtration with flocculation or DE filtration is necessary to remove micro particles after inBlue drum filtration. Typically, 10 to 25 percent of the total flow. Less sand or DE filters mean less energy and water use, resulting in lower overall costs.

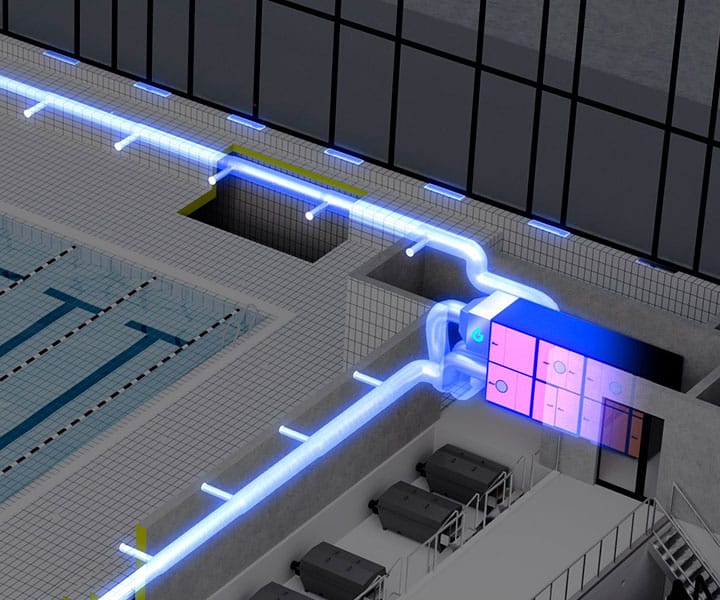

The nitrogen, which originates from urine and sweat, is dissolved and will together with chlorine form chloramines, also called combined chlorine. The ULTRAAQUA POOLRAY, MULTIRAY and ULTRABLUE UV systems ensure that combined chlorine is destroyed, resulting in a dramatic concentration drop. UV filtration thus provides perfect control against Cryptosporidium and Giardia.

THM is formed when chlorine reacts with dissolved organics. The primary THM is chloroform, which can be stripped out even in a small sidestream. The ULTRAAQUA GAS Stripper is designed for this specific task and halves pool THM concentration in a simple and effective way.

Even with every effort to avoid chlorine by-products from forming, we cannot avoid it all. However, with design help from our scientists and engineers, we can create by-product-removing ventilation systems.